[vc_row][vc_column][vc_column_text]

Why Direct Steam Injection Technology can replaces a Sparger in furture?

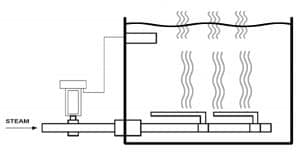

Like the JetCooker™, the sparger heating device relies on the steam from the plant steam supply. Piping from a steam header directs the steam through a sparging nozzle that is located in the process fluid pipe. A common sparging nozzle consists of several holes which allow steam to enter the process fluid and heat it to the desired temperature.

Sparging Drawbacks

Sparging has several disadvantages when compared to the JetCooker:

- Inconsistent steam mixing and heat transfer leading to product inconsistency and wasted energy

- Nozzle clogging which requires maintenance

- Steam hammer leading to process equipment failure

- Imprecise temperature control which translates to higher energy cost

Spargers rely on external modulation by means of a valve to control steam flow and thus process fluid temperature. This type of operation can lead to steam hammer or unit vibration as the steam mixes with the process fluid in the piping or tank. Over time, this can contribute to equipment wear, piping damage and lead to poor performance.

Instantaneous Steam Mixing in a Hydroheater

Another major difference between the Hydroheater and a sparging nozzle can be seen in the mixing process. The Jetcooker utilizes a single nozzle which focuses the incoming steam and accelerates it to a very high velocity (usually sonic velocity) before it comes into contact with the process fluid. This high velocity helps to atomize the steam bubbles and shear the incoming process fluid, which allows for a more complete, efficient heat transfer.[/vc_column_text][vc_separator][/vc_column][/vc_row][vc_row][vc_column width=”1/4″][/vc_column][vc_column width=”1/4″][vc_single_image image=”12710″ img_size=”full”][/vc_column][vc_column width=”1/4″][vc_single_image image=”12712″ img_size=”full”][/vc_column][vc_column width=”1/4″][/vc_column][/vc_row][vc_row][vc_column][vc_custom_heading text=”Spargers can cause significant damage to your tank walls” font_container=”tag:h2|text_align:center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Comparison Chart

| Typical Tank Heating | Hydroheater® Tank Heating |

| DAMAGE | NO DAMAGE |

| With spargers and other less sophisticated direct steam heaters, bubbles form and collapse on tank walls; causing hammer and damage to the tank and peripheral piping. | The Hydroheater’s patented technology produces steam velocity that mixes steam and water very effectively, eliminating steam hammer from uncondensed steam. This ensures a smooth and efficient heating process. |

| HOT/COLD SPOTS | PRECISE/UNIFORM HEATING |

| Spargers inject steam into one area of the tank, causing hot and cold spots. Both spargers & heat exchangers tend to over or under heat and accurate temperature control is difficult. | Hydroheaters precisely modulate the steam – heating to exact temperatures and maintaining uniform heating throughout the tank. Hydroheaters can be used to fill or recirc/trim heat the tank to meet and maintain exact temperatures. Hydroheaters can also heat the discharge on demand, so you only heat the water you need in a single pass. |

| ENERGY LOSS | ENERGY EFFICIENCY |

| Sparging causes uncondensed steam bubbles to evaporate to the atmosphere, wasting large amounts of energy. This lost heat/condensate can also corrode peripheral piping, ceilings and structure. This lost steam can cause hazardous mold & other allergens to build in an area. | Less steam used: Hydroheaters use less steam than heat exchangers because they don’t have a barrier between liquids. Better heat transfer: Hydroheaters transfer 100% of the steam’s energy directly to the process fluid so there is no energy loss. Faster start-up: Hydroheaters heat the tanks faster and more efficiently saving cycle or batch time. |

| HIGH MAINTENANCE | LOW MAINTENANCE |

| Spargers can cause severe hammering and vibration which produces tank and piping damage. Heat exchangers require costly hard water scale maintenance and unwanted down time. Less sophisticated direct steam injection devices often need acid baths and are often high in maintenance needs. | Patented technology to create sonic velocity of steam prevents hard water scale and unwanted down time. Proper sizing of the heaters and internal modulation ensures a smooth heating process so tanks and peripheral pipes are not damaged from hammer and vibration. The heater itself only needs a once a year preventative maintenance check and soft parts change. Wear parts should last up to 3 years with proper operating conditions. |

| Utilizing less steam, space, time means faster cycle times and less costs associated with heating tanks. | |

[/vc_column_text][/vc_column][/vc_row]