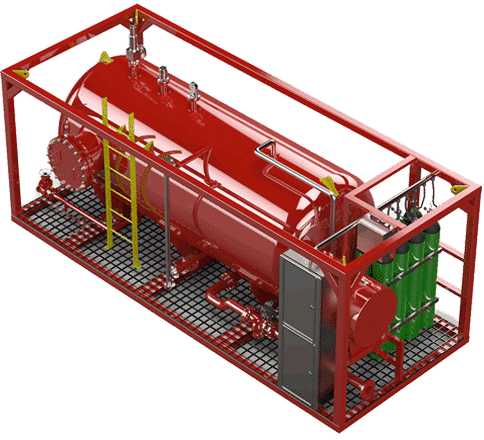

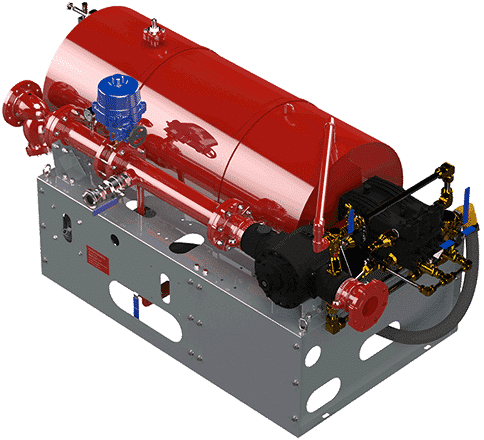

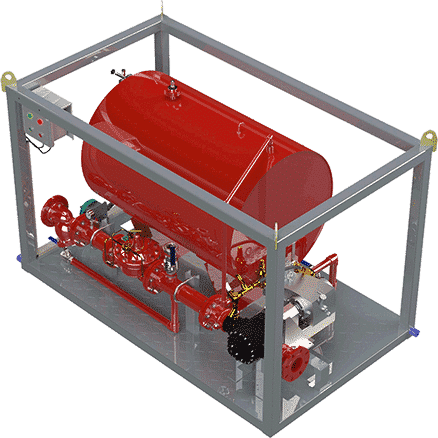

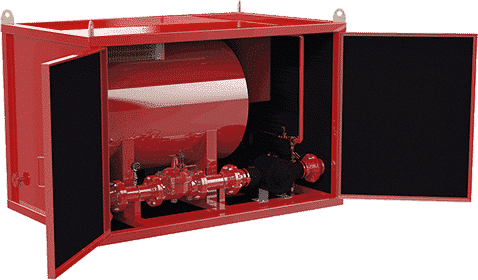

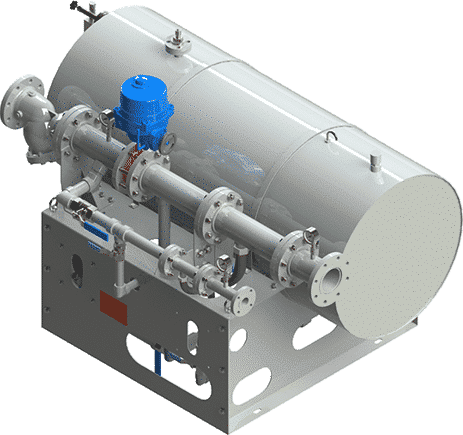

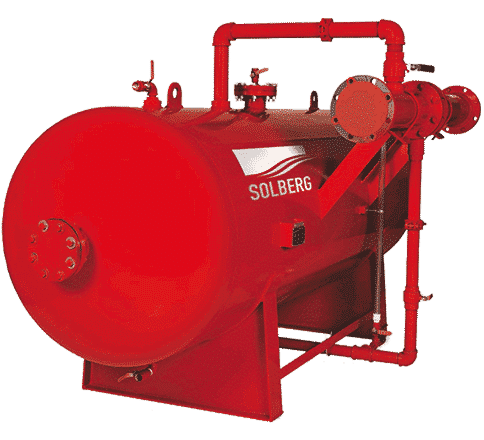

Foam Tank Skid

Foam tank skid DiFF system is proposed with various skid option based on project requirement. The foam tank skid DiFFS system are configured based on parameters such as type of foam proportioning, isolation valve, foam tank capacity, temperature requirements.