Destec G-Range Clamp Connectors

by nhanvietjsc

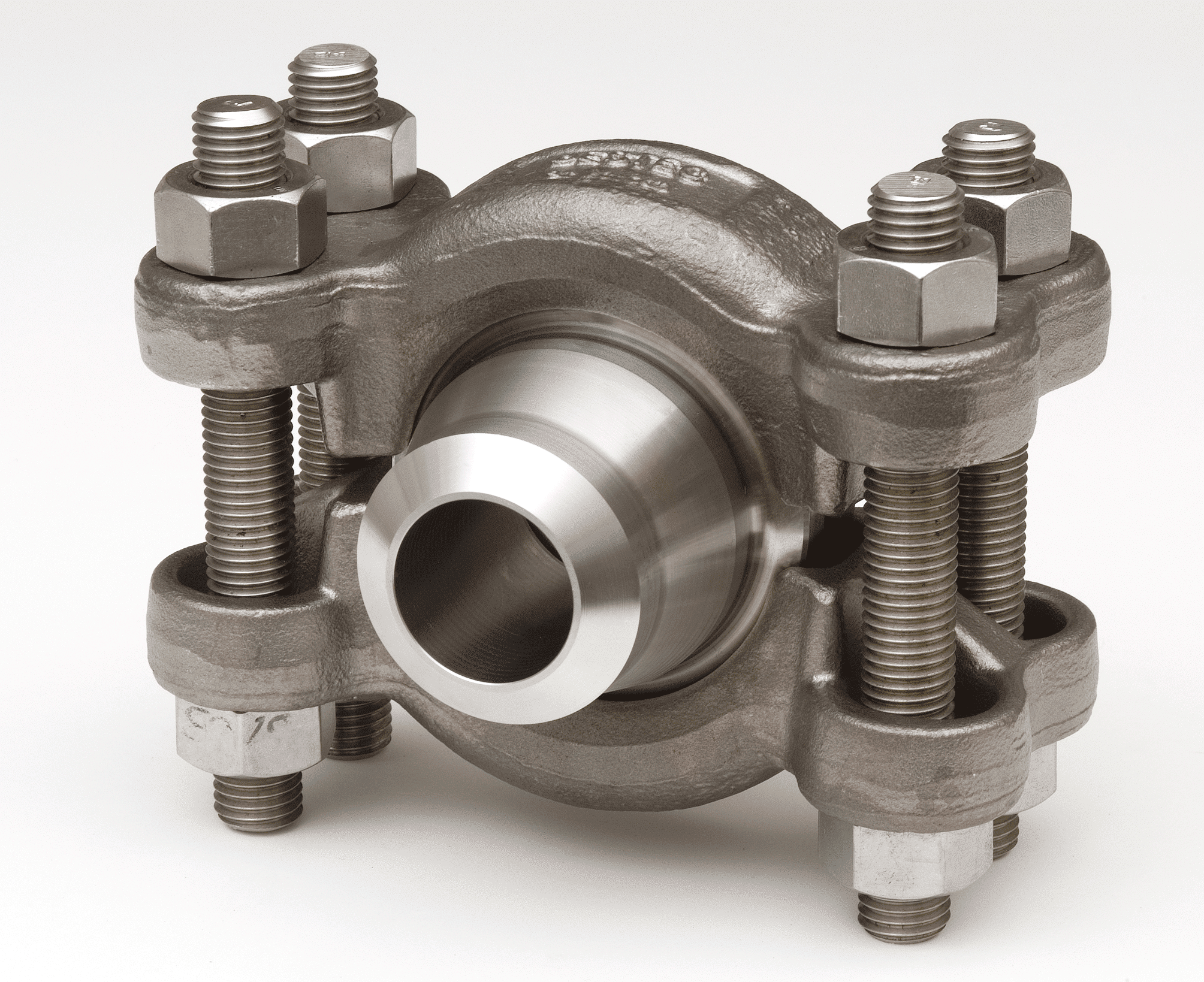

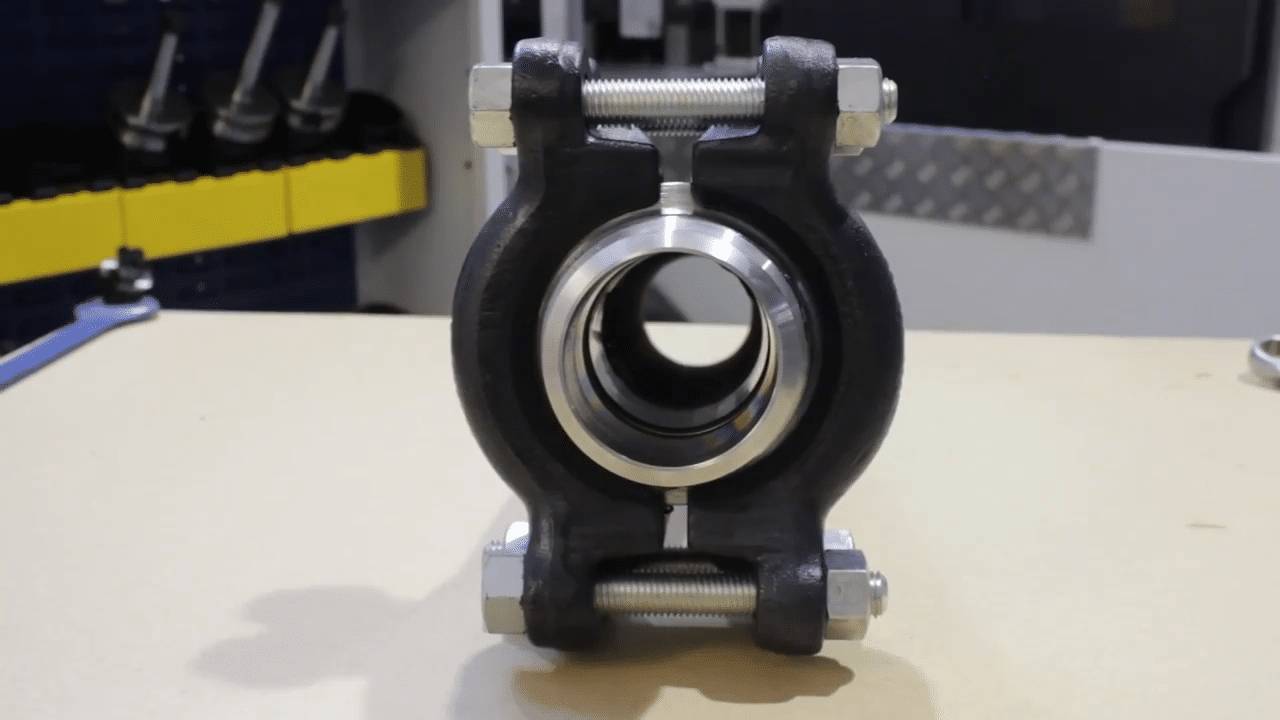

G-RANGE HUB CLAMP CONNECTORS

Designed to meet the requirements of plant operators.

Due to their efficiency, lightness and reliability, together with extreme qualities of leak tightness, the G-Range pipe connection offers significant benefits for use in industrial plant in a wide variety of applications. Although designed primarily for adverse pressure and temperature conditions, more modest applications can be considered due to ease-of-installation and assembly, particularly when compared with the alignment and tightening of standard flanges.

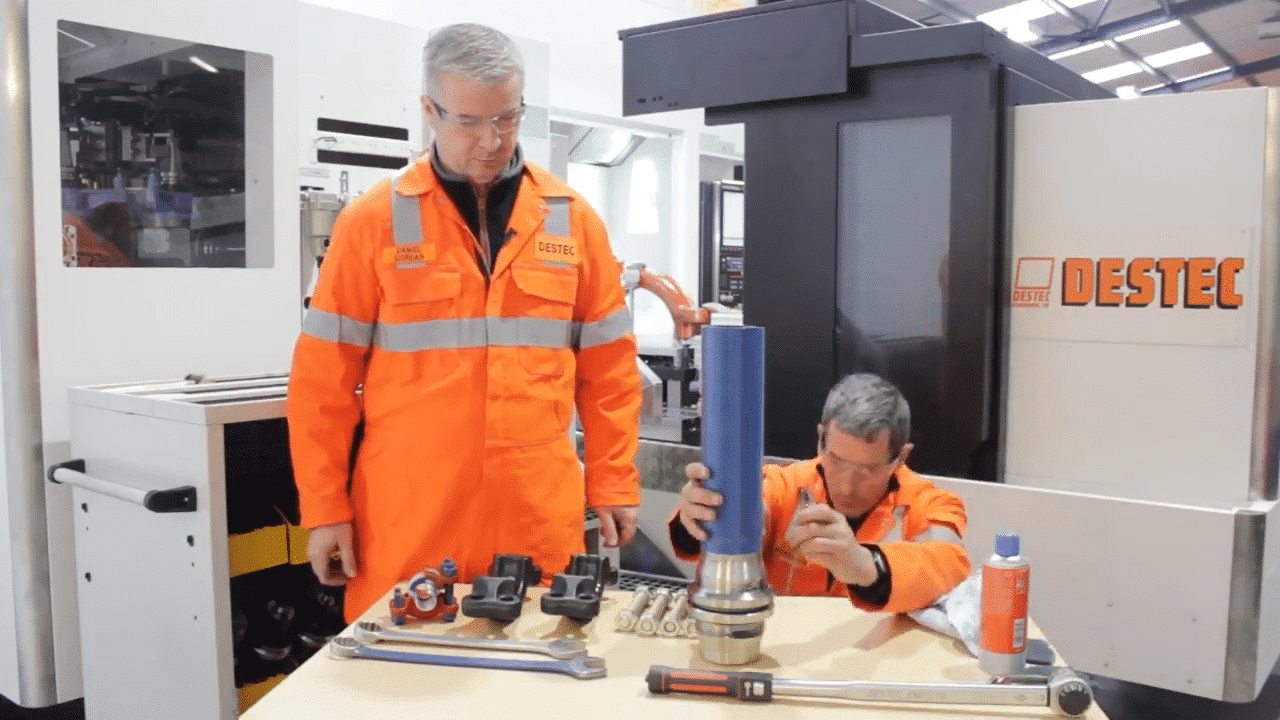

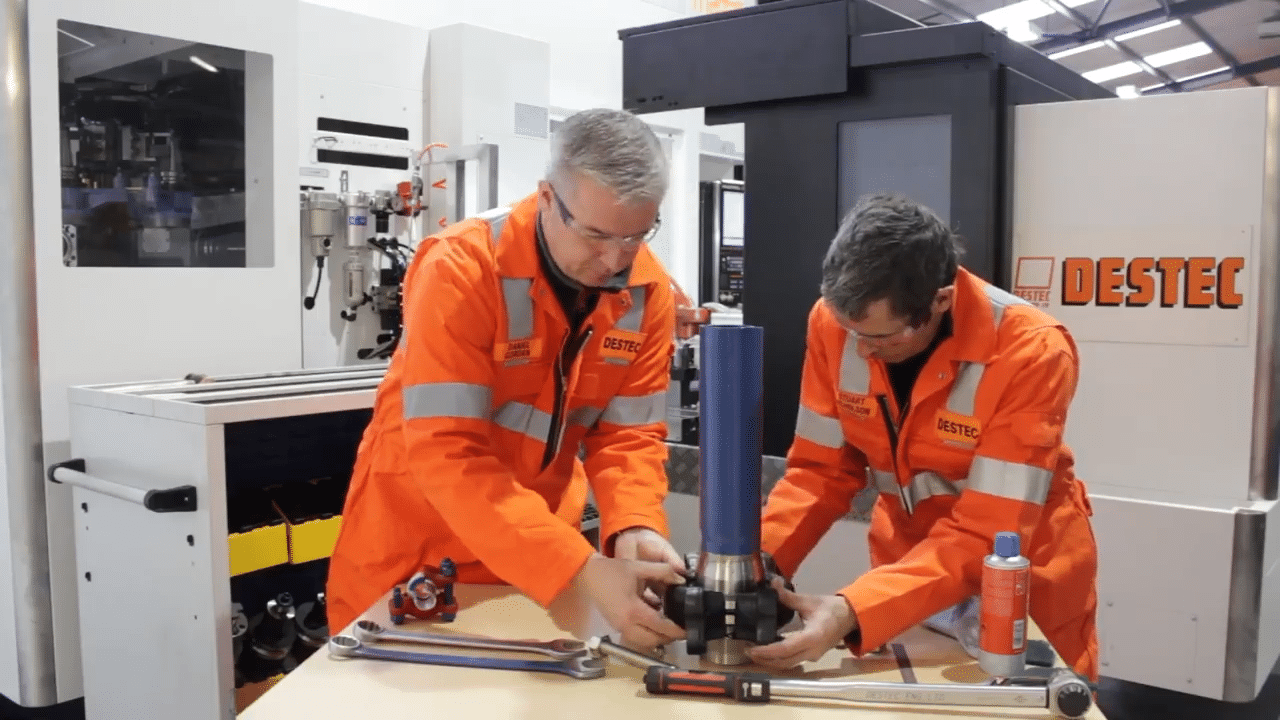

The G-Range pipe connection comprises: a pair of hubs for welding to the pipe (similar to a flange); a clamp set, which can be rotated around the hubs to suit the most practical positions; and a seal ring.

The seal ring is a modified cone ring giving excellent leak tightness properties under the most severe conditions of pressure and/or thermal shock.

On assembly the taper joint faces compress the seal ring radially. The sealing force is provided by the stored energy in the stressed seal ring, any internal pressure intensifies the sealing action.

Weight Saving

Using high strength alloy clamps and flush bore seal rings, minimum fluid seals areas and low make up loads are achieved allowing smaller and more compact units than flanges of equivalent pressure ratings.

Resistance to Pressure and Thermal Shock

Cold quench conditions and thermal cycling are the cause of most leakage problems, where conventional compressible type joints and seal materials are used. The flexibility of the seal ring compensates for this during thermal transient conditions.

High Pressure Containment

The higher the pressure, the more effective the G-Range connection becomes, as internal pressure intensifies the seal.

High Temperatures

The standard ‘all-metal’ seal ring is suitable for most applications – maximum temperatures are limited only by the connection materials selected.

Extreme Leak Tightness

The seals remain leak tight under the most arduous conditions of pressure, temperature and vacuum conditions, even after many thousand hours of operation.

Materials

Destec G-Range connections are supplied in these standard materials. Destec Seal Rings are supplied coated with either PTFE, Molybdenum Disulphide or Graphite, depending on the application. Special G-Range connections are manufactured in many materials including Duplex steels and Nickel-based alloys.

| Pipe Material | Carbon Steel / Carbon Manganese Steel | Stainless Steel 316 type | Duplex (22% Cr) | Super Duplex (25% Cr) | |

| up to 300˚C | over 300˚C | ||||

| HUBS | A350-LF2 (modified) | A182-F316 | A182-F316 | A182-F51 | A182-F53/F55 |

| CLAMPS | A29-4140 | A29-4140 | A182-F304 | A29-4140 | A29-4140 |

| STUDBOLTS | A193-B7 | A193-B7 | A193-B8 | A193-B7 | A193-B7 |

| NUTS | A194-2H | A194-2H | A194-GR8 | A194-2H | A194-2H |

| SEAL RINGS | AISI 4140 | A564-630 | A638-660 | INC 718 or 725 | INC 718 or 725 |

Seal Rings – Orifice, transition, blind.

Clamp Sets – Heavy duty, quick release.

Hubs:

- Heavy Duty.

- Nozzles.

- Threaded.

- Socket weld.

- Reducing.

- Enlarging.

- Tees and Elbows.

- Adaptors.

Many special connections, in a variety of materials, are manufactured to enhance the standard range, for example:

- SHROUDED BORE

- JACKETED

- FLOW THROUGH JACKETED

- EXTREME PRESSURE

- QUICK RELEASE

- REMOTELY OPERATED

- HINGED VESSEL CLOSURES

- ORIFICE CONNECTIONS

Destec will design special G-Range connections to meet customers' requirements.

Re-Usable Seal Rings

The ‘all-metal’ seal ring is elastic in design, and, on dismantling, reverts to its original form, ready for re-use. All seals of given size are interchangeable without any pre-fitting.

Special Connections

Existing troublesome flange joints can usually be converted on site to incorporate the Destec seal ring, as can vessel and heat exchanger closures. Destec seal rings are currently in use up to 2m diameter (2000mm).

Recommended Posts

Check out Destec Products list

October 7, 2019

DESTEC Engineering Vietnam

September 18, 2019

FPI Mag Flow Meter from McCrometer

November 22, 2023