[vc_row][vc_column][vc_column_text]

Why Direct Steam Injection Technology can replaces a Heat Exchanger in furture?

Documented energy savings of up to 30% have been reported when replacing a shell-in-tube or plate and frame heat exchanger with a direct steam injection heater from Hydro-Thermal.

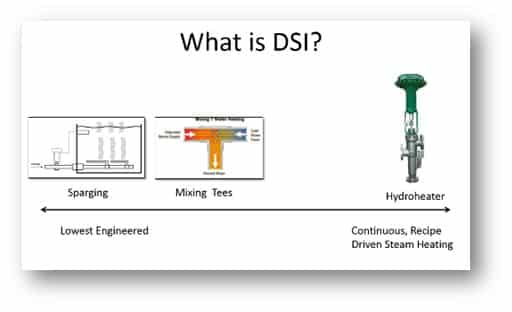

Heat exchangers heat through a metal barrier which does not allow complete energy transfer. On average, 20% of the energy (sensible) is lost to condensate and has to return to the boiler. Direct steam injection heaters are more energy efficient by using 100% of the steam’s energy to heat process fluids or utility water. Hydro-Thermal direct steam heaters are not the conventional steam eductors, but a patented 3-way valve with major advantages over all other fluid heating methods, and providing 100% thermal efficiency.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”12698″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Energy savings with Hydro-Thermal direct steam injection heaters:

A steel mill saved 170,000 mBTU’s per day when replacing a tank sparger with direct steam injection heaters from Hydro-Thermal. That equated to dollar savings of $56,000 per month!

A pulp and paper mill saved 35 minutes each shift bringing process fluid up to set-point temperature using direct steam injection instead of a shell and tube heat exchanger. Daily production increased by 32%.

A food company saved 24 maintenance days per year heating process water for a can-topping process after replacing a competitor’s 3-way steam valve.

More reasons to replace heat exchangers or spargers with a steam injection heater from Hydro-Thermal:

- Less maintenance and more up time

- Exacting control of required process conditions and temperature

- Smaller footprint

- Hydro-Thermal expertise, training, support services and warranty

Eliminate Hot Spots on a Heat Exchanger

Does your heat exchanger unevenly heat?

Because heat exchangers use indirect heat transfer through surfaces, they become coated with product or hard water scaling causing the heat exchanger to loose efficiency. Hot spots and cool spots may also occur resulting in uneven heating and poor product quality.

Due to our patented self-cleaning design, replacing a heat exchanger with direct steam injection steam cookers solves these problems. A baby formula maker increased product quality and the bottom line when they switched from a heat exchanger to our Jetcooker™.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_single_image image=”12700″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Does your current 3 way valve steam heater scale and foul?

Some steam heaters foul and scale because of their inner workings and spring parts causing them to clog and need frequent acid baths. This reduces productivity and increases maintenance costs.

Replacing these heaters with a Hydro-Thermal Hydroheater solves this problem because it is the only one with a unique stem plug and diffuser allowing it to inject precise amounts of steam at sonic velocity via choked flow causing a self-cleaning action. When properly sized for the process conditions and the application, our energy efficient steam heater virtually eliminates scaling and fouling making it the most reliable process heater on the market.

A food processing plant replaced our competitor’s 3 way valve with our heater and increased up-time by 20%![/vc_column_text][/vc_column][/vc_row]